With the new flame retardants test, is it only the outer upholstery fabric which should pass the test, or does it apply the filling materials too?

This is a question commonly asked by customers wondering which layers in upholstery need to pass the test – the cover fabric, the batting the foam, or all three.

Here’s the quick answer – according to my own interpretation of the legal jargon of this Standard:

- To meet the criteria of the ‘new’ (TB 117-2013) California flame retardant standard, the furniture’s cover fabric is tested first, in the smolder test (as in a smoldering cigarette).

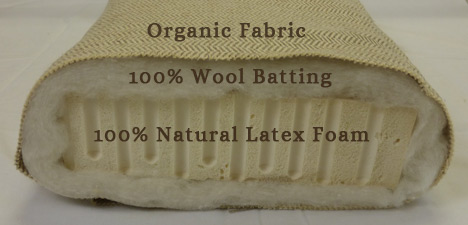

- If a furniture manufacturer’s cover fabric fails this first test, then the next layer under the fabric is tested. Let’s say the cover fabric is Oeko-Tex certified organic cotton. It will NOT pass the smolder test, since cotton is highly flammable. Then let’s assume the next layer is our Oeko-Tex certified 100% Natural Dunlop Latex foam, which is not treated with flame retardant or any other toxic chemicals. In this case, the latex foam will NOT pass the test either. For a commercial furniture manufacturer, the Standard would then require that the latex foam be wrapped in a flame retardant barrier material which does pass the test. In our ‘natural upholstery’ case, the Premium Wool Batting layer placed between the untreated cover fabric and the latex foam would allow the furniture to pass the test, since wool is naturally flame retardant.

- If both cover fabric and foam pass the test, then the interliner, or flame retardant barrier material is not required. This scenario is not going to happen in our non-toxic upholstery case because rubber is flammable AND organic cotton is flammable, so you would need that layer of wool in between.

If you look at a cut-away of an ‘organic’ furniture manufacturer’s layers, you’ll see something like this:

For Vegans, I’m sorry I don’t know of a commercially acceptable non-petroleum based natural upholstery barrier material that does not come from animals. Please let me know in the comments if you have anything to suggest. Perhaps there is a naturally flame-retardant mushroom based product out there that can provide the light-weight loft necessary for this application, or..?

Who does the TB 117-2013 flame-retardant Standard apply to?

As I understand it, this Standard applies to furniture sold commercially in the state of California. There is currently (2016) no national Standard, though other states may have similar requirements. If you are doing upholstery for your personal use, the standard provides a useful guideline for safety. If you’re in the upholstery business, further research is recommended. Please refer to the full context of the Standard for legal requirements. The Green Science Policy Institute is also a great place to find additional information.

For more on flame retardants, see:

- Flame Retardants and your Furniture – Improving your Indoor Environment

- How to Avoid Harmful Flame Retardant Chemicals in your Furniture

If this post has been helpful to you, or if you have questions, personal experience or knowledge to share, please post them in the comments below. Thanks for stopping by! If you’d like to learn more about making your own upholstery more home-health friendly through our monthy newsletter, sign up for our mailing list.

Leave A Comment