How hemp fiber is produced.

Hemp fiber (the precursor to fabric) is produced by essentially the same process as linen, which is produced from flax, another bast fiber. After cultivation & harvesting, the steps in fabric production are:

- Retting – harvested stalks are left in the field (either soaking in water, or letting dew fall on the crop) for 10-20 days to allow naturally occurring bacteria and fungi to break down the pectins that bind the fibers together. When retting is complete, the long fiber bundles separate from the woody core and divide easily into individual finer fibers for their full length. Once this process is complete (dry), the stalks are collected and sent to the “decortication” machine.

- Decortication (breaking) – the dried stems are broken through a mechanical process.

- Scutching – the fiber is separated from the woody core by beating the broken stems, or passing them through rotary blades.

- Softening – decorticated fibers are passed through a roller to make them softer, and aligned for spinning.

- Hackling – tangled fibers are combed (‘hackled’) to remove any woody particles, and long fibers are aligned and smoothed into a continuous ‘sliver’.

- Roving – The ‘sliver’ is twisted and drawn out further to improve strength, then wound onto bobbins.

- Spinning – finer yarns are obtained by wet spinning, in which the fibers are passed through a trough of water as part of the spinning process. Dry spun fibers generally produce a coarser yarn.

Industrial Hemp vs. Recreational Hemp (Marijuana) – What’s the difference?

Industrial hemp (Cannabis sativa)

Different cultivars of the same plant

Hemp fiber grown for textiles and hemp grown for the psychoactive chemical THC are derived from the same plant: Cannabis sativa.

HOWEVER… the divergent cultivation practices that optimize for fiber strength over THC content means that the industrial hemp cultivars used in textile production do not have enough THC to create any psychoactive effects.

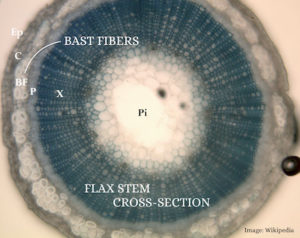

Bast Fibers

Hemp & Flax are both known as bast fibers. Note: linen is produced from the flax plant

The stalks of bast (hemp or flax) consist of two layers:

Cross-section of a flax (linen) fiber

- an outer layer of rope-like bast fibers – the part used for fabric/textile production

- a woody pith/core – the part used in building materials

Hemp & Flax (linen) fabrics both require laborious production steps. Resulting textiles can vary greatly in strength & quality, depending on seed variety, growth conditions, harvest time, retting method, and other factors.

Yarns

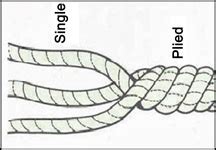

Bast yarns are graded from A (best quality) to D. Strength & quality ratings consider number of twists per unit length, and whether yarn is single or plied (plied = multiple strands of fiber twisted together).

single and plied yarn

Hemp vs. Flax

6 Similarities between hemp & flax (linen) fabrics

- both have strong fibers

- hollow fibers make both natural insulators (cool in summer / warm in winter)

- both have anti-bacterial properties

- both are insect resistant

- both are biodegradable

- both soften through wear & handling

6 Differences between hemp & flax

- hemp fibers are longer (4-7 ft) than those of flax (1.5-3 ft))

- hemp is highly resistant to rotting, mildew, mold and salt water

- hemp is highly resistant to ultraviolet light, and will last longer when exposed to direct sunlight (I know a tipi maker who swears by hemp canvas as her primary cover material)

- hemp has very little stretch – the least of any natural fiber

- hemp grows well without the use of chemicals because it has few serious pest problems (though it is not totally pest-proof as some accounts suggest – nothing is)

- hemp is higher priced than linen

Hemp stalk fiber + core separated

Hemp & Flax from a farming perspective

Farmers claim that hemp is an excellent rotation crop because:

- its long (3+foot) tap root prevents soil loss through run-off and aerates the soil

- its densely spaced growth habit builds topsoil

- it keeps the land free of other weeds

- it keep the soil in good tilth (soil stability, moisture content, degree of aeration, etc)

Flax has lower nutrient requirements than hemp as a crop:

- Nitrogen requirement: 80-100 KG/hectare – hemp, 60 KG/hectare – flax (linen)

- Phosphorus: 100 KG/hectare – hemp, 30-50 KG/hectare – flax

- Potassium: 150 KG/hectare – hemp, 70-100 KG/hectare – flax

Industrial hemp in the field

Certified or not?

When all is said & done, the natural sustainability of growing a particular crop is secondary to the methods used in fabric production. No matter how ‘clean’ a natural fiber crop is, once a fiber enters the fabric production cycle, without GOTS certification, unknown inputs are pretty much guaranteed:

- As much as we might like to believe otherwise, fabric production CAN & DOES involve slave labor, as well as other social justice issues.

- There are thousands of chemicals that go into the various steps of textile production – including formaldehyde anti-wrinkle agents, phthalate coatings to promote flexibility, heavy metals in dyes, PFAS stain resistant coatings, and fire retardants, to name a few.

When human health and social justice are considered, third-party verified GOTS certification is more important than a strictly crop-based sustainability rating. GOTS certification is the best way to assure that NONE of the above (nor myriad other) chemicals or social practices are part of the fabric production process. OekoTex certification is the next best certification, though its requirements fall far short of GOTS.

I know.

We have a small problem…

These certifications are not currently widely available for upholstery fabrics (notable exception: Two Sisters Ecotextiles).

What to do?

ASK.

Next time you purchase (hemp or any other) fabric for a project, ASK your supplier, the store, WHEREVER you are buying from – “Does this contain chemicals that may be harmful to my family’s health?”

Chances are, the person you ask won’t know the answer, and may try to dismiss your question as unimportant. This is where you ASK them to ASK – to find out the answer for you.

This is the important part. Whether you end up making the purchase or not (yes, certified fabrics ARE more expensive), ASKING is how we as consumers can influence changes in the system. When you press for an answer, the question moves up, and you can bet the folks at the top level of (most) companies CARE about their customers’ concerns.

Enough people ASKING creates change.

What if there were a shift, moving government subsidies AWAY from corporations that lobby to maintain the status quo (eg. big petroleum companies), and TOWARD sustainable farming practices that preserve our lands’ biodiversity for future generations.

Transparency is the key.

Check out Two Sisters Ecotextiles for GOTS & OekoTex certified fabrics.

Find more detail on traditional hemp textile production and history at Recreator.org

Join NaturalUpholstery.com’s mailing list to receive our newsletter featuring stories from the upholstery community, plus tips, creative inspiration, and resources.

Hi Carla

Thanks again for this wonderful information. Also, thank you for your videos about upholstering with woollen batting and natural latex- fabulous!