Both Talalay & Dunlop can be either 100% Natural or Blended Latex

Talalay & Dunlop are two different manufacturing processes used in the production of latex foam. It’s important to note that both processes are used in the manufacture of both 100% Natural AND blended synthetic/natural latex foam. So be sure to ask about the ingredients before you buy. A blended or synthetic latex will contain petroleum product in the form of polyurethane or styrene butadiene rubber (SBR).

Before I address the differences, I want to quickly answer one ‘burning’ question that a lot of people have about latex:

Why the holes in latex? Here’s your answer.

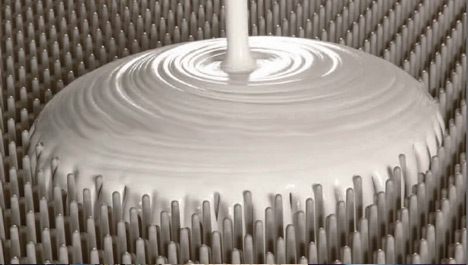

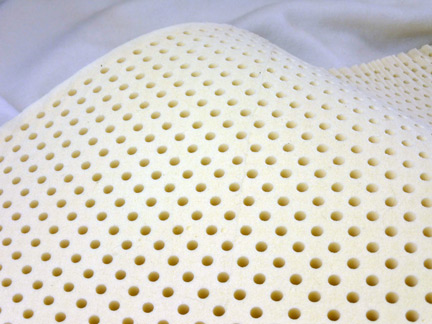

Why are there Holes in Latex?

Both the Talalay & Dunlop processes use steam to ‘cook’ the latex. The pin core structure of the mould acts to evenly distribute the heat during vulcanization (like a waffle iron), which prevents scorching of the rubber and creates the signature holes in the finished product.

All natural latex foams have ‘pin-holes’

Now for the comparison:

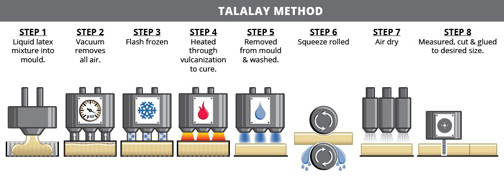

The Talalay Process

In the Talalay process, the raw liquid latex is whipped into a froth along with the necessary curing agents and additives, which is then injected into the latex mold. The air is extracted (via vacuum) to evenly distribute the foamed liquid throughout the mold to create a consistent, open-cell structure. The latex is then flash frozen to lock the cell structure in place and prevent any settling that may occur. Introduction of CO2 (carbon dioxide) causes the mixture to gel, and finally, the latex is vulcanized and cured.

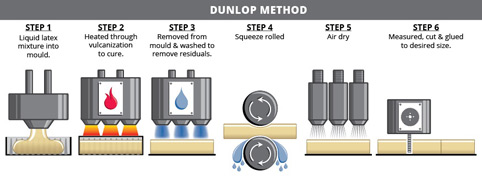

The Talalay latex process entails vacuum & freezing steps which the dunlop process omits (thanks to sleepacademy.org for this image)

The Dunlop Process

In the Dunlop process, the injection mould is filled to the brim and there is no vacuum or freezing stage. This creates a denser, less “airy”, firmer feeling product, with a somewhat less even distribution of latex.

Is One Better than the Other?

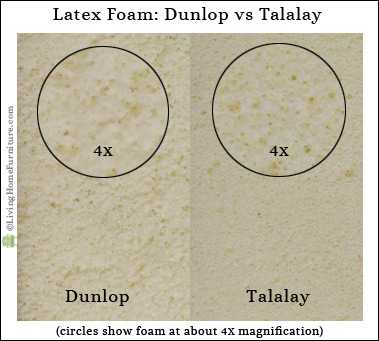

There are many who say that the Talalay process results in a higher quality product. My personal observations are that that the Talalay foam has a smoother and more uniform texture than the Dunlop foam, has slightly more stretch and is a bit less prone to tearing. A drawback is the finer textured Talalay does not hold up as long, showing ‘impressions’ sooner. Most important for my consideration is the lack of a GOLS organic certification for any Talalay product

Dunlop latex is produced at a lower cost, while still providing the unique comfort, durability and health benefits that have made latex foam so popular. Dunlop is the only latex process that meets GOLS organic certification requirements.

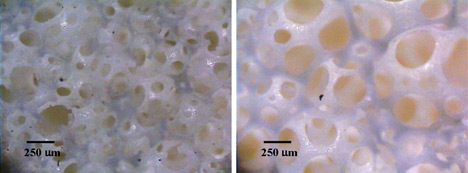

It’s a bit like comparing sponge cake to pound cake: Talalay is more light & airy, like sponge cake, while Dunlop is more dense, like pound cake. I found this magnified comparison at Flobeds.com

Here’s my own comparison, at lower magnification:

The Dunlop latex has a ‘coarser’ cell structure than the Talalay latex foam

The Bottom Line for Talalay vs Dunlop Latex for Upholstery

I have used both Talalay and Dunlop in upholstery projects, and it’s apparent that Talalay latex is a lower density product, supporting the view that Talalay will not last as long as the higher density Dunlop latex. Here’s a quick reference comparing the two:

Both Talalay & Dunlop 100% Natural Latex:

- Health benefits: anti-microbial, hypo-allergenic, dust mite resistant

- Durability: outlasts ‘conventional’ polyurethane foam with proper application (protect the foam from exposure to high heat and sunlight)

- Comfort: ‘breathable’ cell structure, resilient structure of natural rubber imparts a ‘bounce’ that is unique to natural latex

Talalay:

- slightly softer overall feel than Dunlop

- more uniform grain/texture

- more ‘springy’ feel overall

- more expensive process

Dunlop:

- slightly firmer overall feel than Talalay

- coarser grain

- less expensive process

- Dunlop is the only latex foam currently available as a certified organic product by GOLS (Global Organic Latex Standard)

Read more about Latex Pros & Cons on The Mattress Underground.

Ready to learn more? Subscribe to my email newsletter for upholstery tips and videos.

Leave A Comment